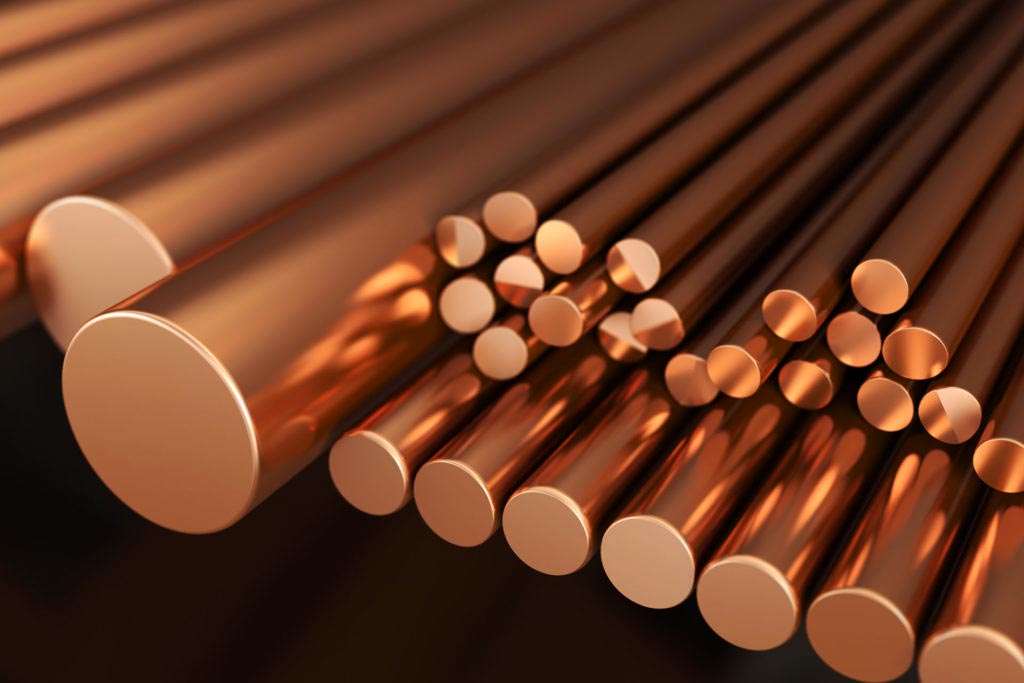

Wires & Cables

- Power transmission lines

- Architectural applications

- All kinds of household electrical equipment

- All kinds of lighting equipment

- High-voltage electrical wiring

The numerous applications of these copper cables and wires have caused the number of their users to increase every day in the markets and their production to meet the needs of the markets has reached a high level, it is worth mentioning that these cables have very high resistance They are resistant to heat, fire and humidity and they have always been able to be used for many activities without quality loss.

There is a wide variety of copper wire in the market, and one of its types is stranded wire. Stranded wire is made and produced by twisting a large number of thin and soft copper strands together. The wire is produced from a conductor and a coating, the conductor of which is made of copper. The cover that insulates the copper conductor is made of PVC.

Solid wire is a copper strand with a round cross-section. In addition to being soft and flexible, this type of copper wire is very strong and resistant, malleable and conductive. Therefore, rolling and stretching methods are used to form these types of wires. The main use of copper wire is in the construction industry.

Flat wires have entered the industry for a short time. The way of placing this bunch of wires together is such that it creates a flat cross-section with the insulation. Due to their special shape, these wires are less vulnerable than wires with a round cross-section.

The production process of wires and cables in factories is almost the same. Of course, according to the type of wire and cable, the process can be slightly different. The production process consists of drawing, annealing, bunching (twisting and stranding), extrusion, cabling and packaging. Each step can be adjusted according to the type of wire or cable that is being produced.

ITAD offers high-quality copper cathodes suitable for wire and cable production.

The meticulous manufacturing process leads to high purity of copper cathodes and the ideal products for wires and cables.

ITAD